Computer-aided design (

CAD), also known as

computer-aided drafting and design (

CADD), is the use of

computer technology for the process of design and design-documentation. Computer Aided Design describes the way in which technology is folded into a design process. Computer Aided Drafting describes the process of drafting with a computer. CADD software, or environments, provide the user with input-tools for the purpose of streamlining design processes; drafting, documentation, and manufacturing processes. CADD output is often in the form of electronic files for print or machining operations. The development of CADD-based software is in direct correlation with the processes it seeks to economize; industry-based software (construction, manufacturing, etc.) typically uses vector-based (linear) environments whereas graphic-based software utilizes raster-based (pixelated) environments.

CADD environments often involve more than just shapes. As in the manual

drafting of

technical and

engineering drawings, the output of CAD must convey information, such as

materials, processes,

dimensions, and

tolerances, according to application-specific conventions.

CAD may be used to design curves and figures in

two-dimensional (2D) space; or curves, surfaces, and solids in

three-dimensional (3D) objects.

[1]

CAD is an important

industrial art extensively used in many applications, including automotive, shipbuilding, and aerospace industries, industrial and architectural design,

prosthetics, and many more. CAD is also widely used to produce

computer animation for

special effects in movies,

advertising and technical manuals. The modern ubiquity and power of computers means that even perfume bottles and shampoo dispensers are designed using techniques unheard of by engineers of the 1960s. Because of its enormous economic importance, CAD has been a major driving force for research in

computational geometry,

computer graphics (both hardware and software), and discrete differential geometry.

[2]

The design of

geometric models for object shapes, in particular, is often called

computer-aided geometric design (

CAGD).

Overview

Current computer-aided design software packages range from 2D

vector-based drafting systems to 3D

solid and

surface modellers. Modern CAD packages can also frequently allow rotations in three dimensions, allowing viewing of a designed object from any desired angle, even from the inside looking out. Some CAD software is capable of dynamic mathematic modeling, in which case it may be marketed as

CADD —

computer-aided design and drafting.

CAD is used in the design of tools and machinery and in the drafting and design of all types of buildings, from small residential types (houses) to the largest commercial and industrial structures (hospitals and factories).

CAD is mainly used for detailed engineering of 3D models and/or 2D drawings of physical components, but it is also used throughout the engineering process from conceptual design and layout of products, through strength and dynamic analysis of assemblies to definition of manufacturing methods of components. It can also be used to design objects.

CAD has become an especially important technology within the scope of

computer-aided technologies, with benefits such as lower product development costs and a greatly shortened design cycle. CAD enables designers to lay out and develop work on screen, print it out and save it for future editing, saving time on their drawings.

Occupations that use CAD include designers, architects, and developers.

Computer-aided design is one of the many tools used by engineers and designers and is used in many ways depending on the profession of the user and the type of software in question.

CAD is one part of the whole Digital Product Development (DPD) activity within the

Product Lifecycle Management (PLM) process, and as such is used together with other tools, which are either integrated modules or stand-alone products, such as:

CAD is also used for the accurate creation of photo simulations that are often required in the preparation of Environmental Impact Reports, in which computer-aided designs of intended buildings are superimposed into photographs of existing environments to represent what that locale will be like were the proposed facilities allowed to be built. Potential blockage of view corridors and shadow studies are also frequently analyzed through the use of CAD.

There are several different types of CAD. Each of these different types of CAD systems require the operator to think differently about how he or she will use them and he or she must design their virtual components in a different manner for each.

There are many producers of the lower-end 2D systems, including a number of free and open source programs. These provide an approach to the drawing process without all the fuss over scale and placement on the drawing sheet that accompanied hand drafting, since these can be adjusted as required during the creation of the final draft.

3D wireframe is basically an extension of 2D drafting. Each line has to be manually inserted into the drawing. The final product has no mass properties associated with it and cannot have features directly added to it, such as holes. The operator approaches these in a similar fashion to the 2D systems, although many 3D systems allow using the wireframe model to make the final engineering drawing views.

3D "dumb" solids (programs incorporating this technology include AutoCAD) are created in a way analogous to manipulations of real world objects. Basic three-dimensional geometric forms (prisms, cylinders, spheres, and so on) have solid volumes added or subtracted from them, as if assembling or cutting real-world objects. Two-dimensional projected views can easily be generated from the models. Basic 3D solids don't usually include tools to easily allow motion of components, set limits to their motion, or identify interference between components.

3D parametric

solid modeling require the operator to use what is referred to as "design intent". The objects and features created are adjustable. Any future modifications will be simple, difficult, or nearly impossible, depending on how the original part was created. One must think of this as being a "perfect world" representation of the component. If a feature was intended to be located from the center of the part, the operator needs to locate it from the center of the model, not, perhaps, from a more convenient edge or an arbitrary point, as he could when using "dumb" solids. Parametric solids require the operator to consider the consequences of his actions carefully.

Some software packages provide the ability to edit parametric and non-parametric geometry without the need to understand or undo the design intent history of the geometry by use of direct modeling functionality. This ability may also include the additional ability to infer the correct relationships between selected geometry (e.g., tangency, concentricity) which makes the editing process less time and labor intensive while still freeing the engineer from the burden of understanding the model’s

design intent history. These kind of non history based systems are called Explicit Modellers or Direct CAD Modelers. The first Explicit Modeling system was introduced to the world at the end of 80's by Hewlett-Packard under the name

SolidDesigner.

Draft views are able to be generated easily from the models. Assemblies usually incorporate tools to represent the motions of components, set their limits, and identify interference. The tool kits available for these systems are ever increasing; including 3D piping and injection mold designing packages.

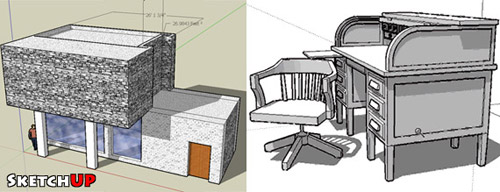

Mid range software are integrating parametric solids more easily to the end user: integrating more intuitive functions (

SketchUp), using the best of both 3D dumb solids and parametric characteristics (

VectorWorks), making very real-view scenes in relative few steps (

Cinema4D) or offering all-in-one (

form•Z).

Top end systems offer the capabilities to incorporate more organic, aesthetics and ergonomic features into designs (

Catia,

GenerativeComponents).

Freeform surface modelling is often combined with solids to allow the designer to create products that fit the human form and visual requirements as well as they interface with the machine.

[edit] Technology

Originally software for Computer-Aided Design systems was developed with computer languages such as

Fortran, but with the advancement of

object-oriented programming methods this has radically changed. Typical modern

parametric feature based modeler and

freeform surface systems are built around a number of key

C modules with their own

APIs. A CAD system can be seen as built up from the interaction of a

graphical user interface (GUI) with

NURBS geometry and/or

boundary representation (B-rep) data via a

geometric modeling kernel. A geometry constraint engine may also be employed to manage the associative relationships between geometry, such as wireframe geometry in a sketch or components in an assembly.

Unexpected capabilities of these associative relationships have led to a new form of

prototyping called

digital prototyping. In contrast to physical prototypes, which entail manufacturing time and in the design.

Today, CAD systems exist for all the major platforms (

Windows,

Linux,

UNIX and

Mac OS X); some packages even support multiple platforms.

Right now, no special hardware is required for most CAD software. However, some CAD systems can do graphically and computationally expensive tasks, so good

graphics card, high speed (and possibly multiple)

CPUs and large amounts of

RAM are recommended.

The human-machine interface is generally via a

computer mouse but can also be via a pen and digitizing

graphics tablet. Manipulation of the view of the model on the screen is also sometimes done with the use of a spacemouse/

SpaceBall. Some systems also support stereoscopic glasses for viewing the 3D model.