From Wikipedia, the free encyclopedia

CAx tools in the context of product lifecycle management

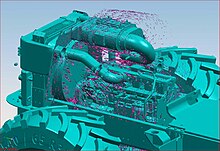

Advanced CAx tools merge many different aspects of the product lifecycle management (PLM), including design, analysis using finite element analysis (FEA), manufacturing, production planning, product testing using virtual lab models and visualization, product documentation, product support, etc. CAx encompasses a broad range of tools, both those commercially available and those which are proprietary to the engineering firm.

The term CAD/CAM (computer-aided design and computer-aided manufacturing) is also often used in the context of a software tool covering a number of engineering functions.

[edit] List of computer-aided technologies

- Computer-aided design (CAD)

- Computer-aided architectural design (CAAD)

- Computer-aided design and drafting (CADD)

- Computer-aided process planning (CAPP)

- Computer-aided quality assurance (CAQ)

- Computer-aided reporting (CAR)

- Computer-aided requirements capture (CAR)

- Computer-aided rule definition (CARD)

- Computer-aided rule execution (CARE)

- Computer-aided software engineering (CASE)

- Component information system (CIS)

- Computer-integrated manufacturing (CIM)

- computer numerical controlled (CNC)

- Computational fluid dynamics (CFD)

- Electronic design automation (EDA)

- Enterprise resource planning (ERP)

- Finite element analysis (FEA)

- Knowledge-based engineering (KBE)

- Manufacturing process management (MPM)

- Manufacturing process planning (MPP)

- Material requirements planning (MRP)

- Manufacturing resource planning (MRP II)

- Product data management (PDM)

- Product lifecycle management (PLM)

- computer-aided manufacture (CAM)

No comments:

Post a Comment